Twisted cotton white rope is a versatile and durable product used in a wide range of applications, from household tasks to industrial uses, due to its strength, flexibility, and natural fibers. The process of making twisted cotton rope involves several steps, each crucial to ensuring the final product is of high quality.

1. Cotton Fiber Selection

The first step in making twisted cotton rope is selecting high-quality cotton fibers. Cotton is a soft, natural fiber that is spun into yarn for rope production. The cotton used for ropes is typically harvested from cotton plants, cleaned to remove impurities, and then spun into yarn.

2. Spinning the Cotton Yarn

Once the cotton fibers are collected, they are carded and spun into yarn. In the spinning process, individual cotton fibers are twisted together to form a stronger and longer thread. The amount of twist in the yarn depends on the desired strength and texture of the rope.

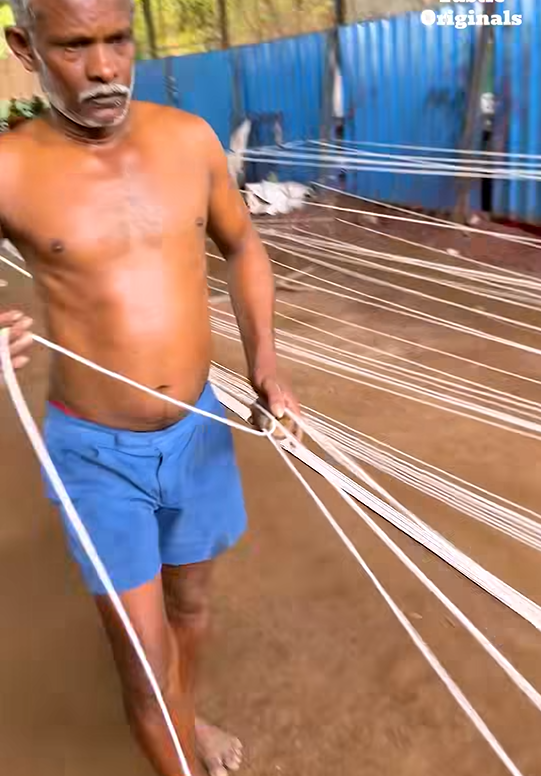

3. Twisting the Yarn into Rope

After spinning, the yarns are ready to be twisted into rope. In this stage, multiple strands of cotton yarn are combined. These strands are laid parallel to each other and twisted in the same direction to create the twisted rope structure. The twisting process is typically done by machines, but in some cases, it may be done by hand, depending on the desired thickness and texture of the rope.

4. Strengthening the Rope

The twisted cotton rope may undergo additional strengthening steps. Some manufacturers apply a protective coating, such as wax or resin, to make the rope more resistant to wear and tear, moisture, and fraying. The rope is also stretched to ensure it can withstand the intended load.

5. Finishing Touches

After the rope has been twisted and strengthened, it is usually washed to remove any excess oils or impurities. The rope is then dried and cut into desired lengths. The final step may include inspecting the rope for any defects and ensuring it meets the required strength standards.

6. Quality Control and Packaging

Quality control checks are performed at various stages of the manufacturing process. The rope is tested for tensile strength, durability, and consistency in thickness. Once it passes inspection, the rope is packaged for shipping, often coiled neatly for convenience.

Conclusion

The making of twisted cotton white rope is a careful, intricate process that combines natural fibers, modern machinery, and skilled craftsmanship to create a product that is both strong and versatile. The resulting rope is highly sought after for its durability, eco-friendliness, and wide range of practical applications.