Marbles, the small, colorful spheres loved by children and collectors alike, have been a part of history for centuries. Today, these delightful objects are produced in factories using advanced technology, but the process still relies on some traditional methods. Here’s a look at how marbles are made in a modern factory.

1. Raw Materials

The process begins with the selection of raw materials. Most marbles are made from a mixture of glass, which gives them their shiny, smooth surface. Other ingredients, such as minerals and dyes, are added to give marbles their vibrant colors and unique patterns. The glass is typically sourced from recycled bottles and other glass products, making marble production an eco-friendly process.

2. Melting the Glass

The glass is heated in a furnace at very high temperatures, usually around 2,000°F (1,100°C), until it melts into a thick, molten liquid. This step is crucial because the glass needs to be at just the right consistency to shape it into perfect spheres.

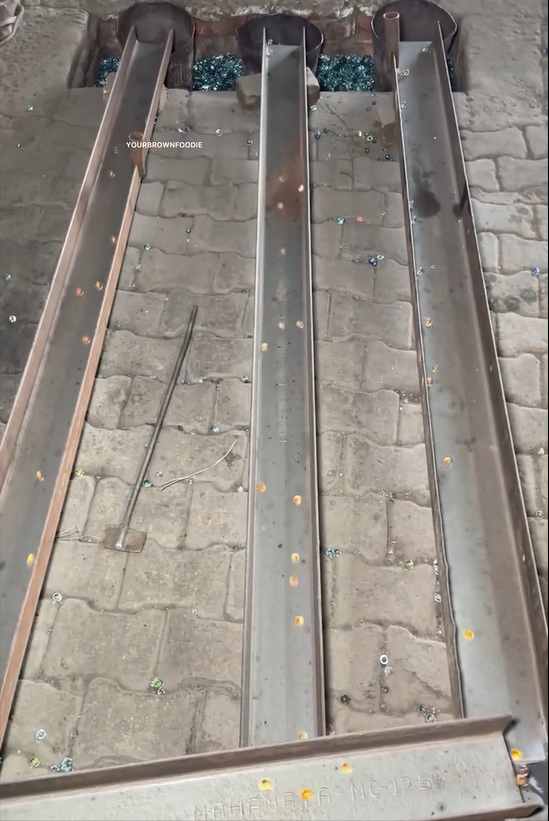

3. Shaping the Marbles

Once the glass has melted, it is carefully dropped onto a machine called a “marble-making machine.” These machines are designed to cut the molten glass into uniform pieces. The glass is then shaped into small balls. Some factories use molds to create the marbles, while others rely on the traditional method of hand-rolling. The size and shape of the marbles are meticulously controlled to ensure consistency.

4. Adding Color and Patterns

At this stage, the factory adds colors and patterns to the marbles. This can be done by incorporating colored glass fragments or powders into the molten glass. In some cases, marbles may be swirled or etched with special designs to create marble varieties like “swirl marbles,” “cat’s eye marbles,” or “solid-colored marbles.” Some marbles even have small designs or logos inside them.

5. Cooling and Hardening

After the marbles are formed, they are gradually cooled in a special kiln. This cooling process, known as annealing, allows the marbles to harden without breaking. The cooling must be done slowly and carefully to avoid any cracks or imperfections in the glass.

6. Polishing

Once the marbles have cooled and hardened, they are polished to a smooth, shiny finish. This is often done in a rotating drum with a mixture of fine grit and water. The marbles are tumbled around in the drum for several hours until their surfaces become glossy and smooth.

7. Quality Control

Before the marbles are packed and shipped, they go through a final inspection. Factory workers check each marble for any defects, such as cracks or uneven coloring. Only the best marbles make it to the packaging stage.

8. Packaging and Distribution

Finally, the finished marbles are carefully packed into bags or boxes and are ready for distribution to stores or collectors. The marbles may be sold individually or in sets, and they often come in a wide range of colors and sizes.

Conclusion

The process of making marbles in a factory combines both traditional craftsmanship and modern technology. From melting glass to shaping, coloring, and polishing, every step ensures that each marble is a perfect little work of art. Today’s marbles continue to bring joy to people of all ages, whether used for play, decoration, or collection.